Verifying the slip, removal and strip torque of metal closures is an essential quality-control step. It not only documents the quality of finished batches to ensure consumers can open the drink but it also serves as a key check when setting up the bottling equipment.

By detecting low or high torque values it is possible to adjust the capping machine accordingly and avoid costly rejects later in the process.

Quality control testing solutions

Our range of test equipment can asses screw cap application and release torque to:

- measure consistency of release torque straight from the production line

- ensure capping machines are set correctly to avoid damaging closures

- minimise risk of oxidation and leakage due to poor fitting screw caps

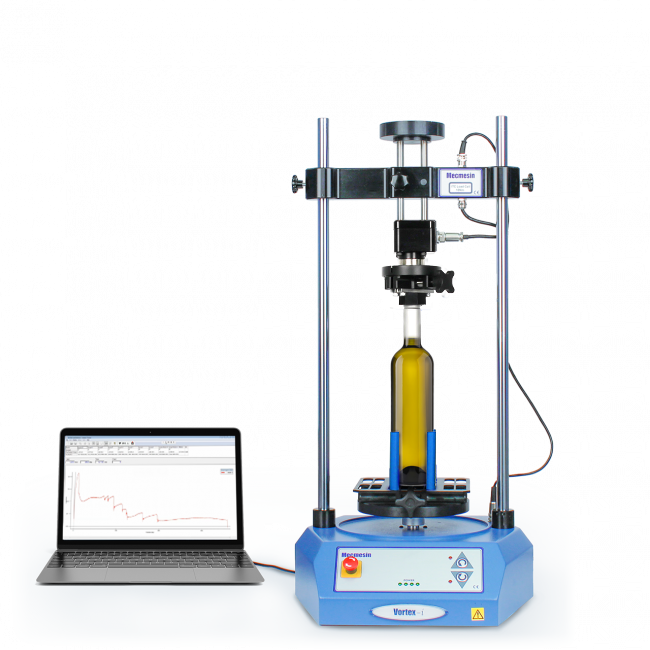

Screw-cap closure testing (ROPP)

Wines sealed by screw-cap closures (eg ROPP - Roll On Pilfer Proof) are quality checked for the torque required to tightly close the bottle, and then open, by breaking the tamper-evident seal.

Manually operated torque meters are widely used in production areas to batch-check bottles regularly coming off the filling lines, or 'first-off' checking a new machine set-up on the filling line.

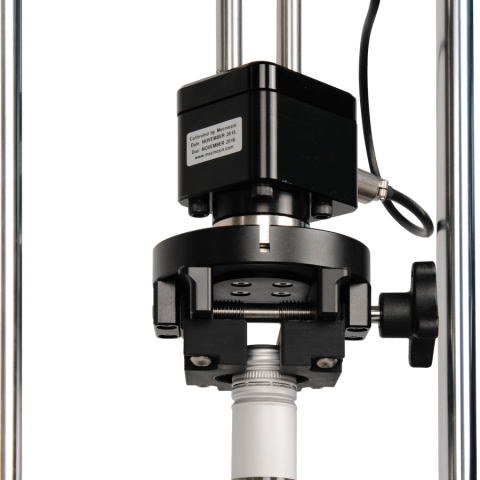

Automated torque testers provide extra repeatability and are often installed in QC laboratories for more in-depth testing.