The winery industry has developed Roll-On Tamper-Evident (ROTE) / Roll-On Pilfer-Proof (ROPP) screw cap designs as alternatives to cork stoppers, aimed at delivering a more consistent and reliable performance.

Ease of opening, resealing convenience, reduction in wine faults and tamper evidence are among the advantages.

Your needs

Your Quality Control areas must have confidence that functional performance is being achieved.

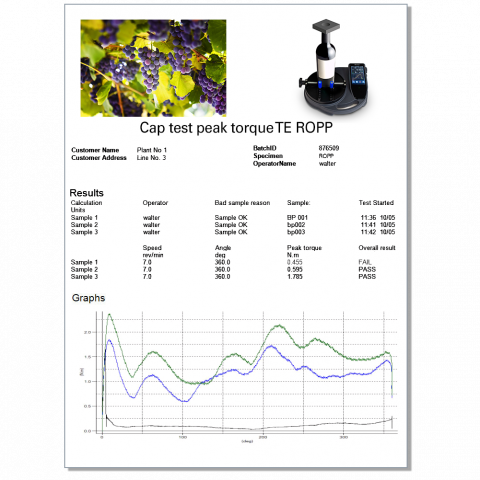

When opening a closure there are 2 distinct phases to be measured. Firstly, the twist effort to overcome the resistance between the liner and the top of the bottle to start the closure moving. Then the torque to break the bridges of the tamper-evidence mechanism as the closure is fully unscrewed.

To identify potential ‘spinners’, the closures are tested for strip torque by tightening them even further.

All tests are performed to established methods and testing standards for comparison against ideal tolerances.

Our solutions

We at Mecmesin have supplied torque measuring instruments and test systems to businesses in the closures sector since the 1990s and in recent years we have expanded our client base to include the wines & spirits industry.

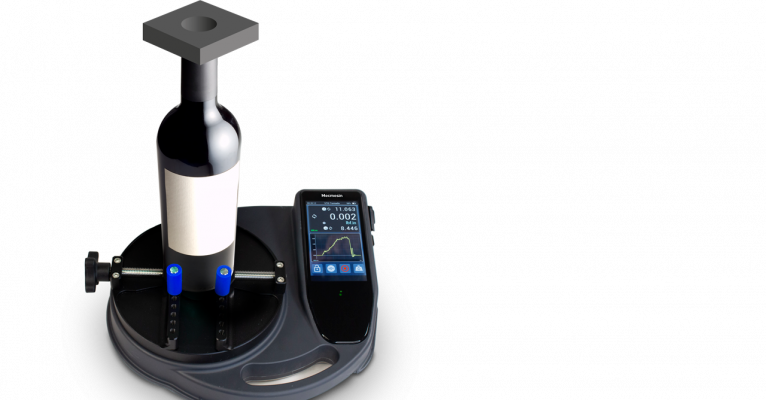

- Simple-to-use manually operated torque testers measure maximum removal torque and TE bridge break. Optional, intuitive drag-and-drop software available to report data and graphical results.

- Semi-automated torque testing systems feature a motor-drive to guarantee a consistent rotation speed for optimum repeatability.

- Software-controlled equipment allows the creation of exact standard procedures or custom methods, detects important events in the torque characteristics, and outputs reports for data auditing.

- Standard fixtures securely hold glass bottles without slippage and mandrel grip caps uniformly to eliminate inaccurate measurement.

- Custom, automated systems test large batches with minimum operator input.

The benefits

Taking control of the in-house testing of the mechanical performance of your wine bottle screw caps can be invaluable. It enables your business to ensure a consistent product irrespective of supplier variances, cuts costs by reducing rejects and keeps production parameters correct, and even tests those new design innovations driven by your evolving customer markets.

Do you want to automate your batch testing?

Our ABC-t automated bottle closure tester measures both initial slip and bridge torque of a complete batch of ROPP closures.