As a producer of cork stoppers—natural corkwood, synthetic or technical—you tailor this closure to the wine you are sealing.

Whether a product for aging or for enjoyment in a shorter timeframe, the chosen stopper must guarantee consistent corking, reliable sealing, and ease of extraction by your discerning customer … the right quality at the right price.

Your needs

Your Quality Control areas must have confidence that functional performance can be achieved for every stopper produced.

The right coating for the cork is vital to its frictional properties when it's inserted at corking and when later extracted by your customer.

The elasticity under compression and expansion in the bottle is vital to sealing when a top-vintage is to be stored for decades before drinking.

These physical attributes must be checked for stoppers you have chosen specifically for their suitability for other characteristics of your wine.

Our solutions

We have a range of instruments to suit every taste

A basic standalone cork pull force tester is easy to use, fitted with a representative corkscrew fixture and a handwheel, any user can extract a sample cork and get an immediate reading of the peak force.

International test standards

The ISO 9727 standard addresses tests for 'cork-extraction force' and 'dimensional recovery after compression', both of which are easily performed on our range of tensile and compression testers.

- Motor-driven test stands perform extraction tests to ISO 9727-5 with utmost consistency and repeatability.

- Automated systems for compression and recovery measurement to ISO 9727-4, feed in and remove complete batches of cork stoppers to the tester.

Cork torque extraction

Torque testing industry guidelines for sparkling wine corks are also in place to help you verify the corks are not so tightly inserted they cannot be removed and, worse still, that they don’t pop out too easily and cause injury.

- CombiCork-dV purpose-built tester reliably and objectively measures the release torque when extracting a cork from a sparkling wine or spirits bottle. It represents the helical action of a consumer by combining a simultaneous twist and pull motion.

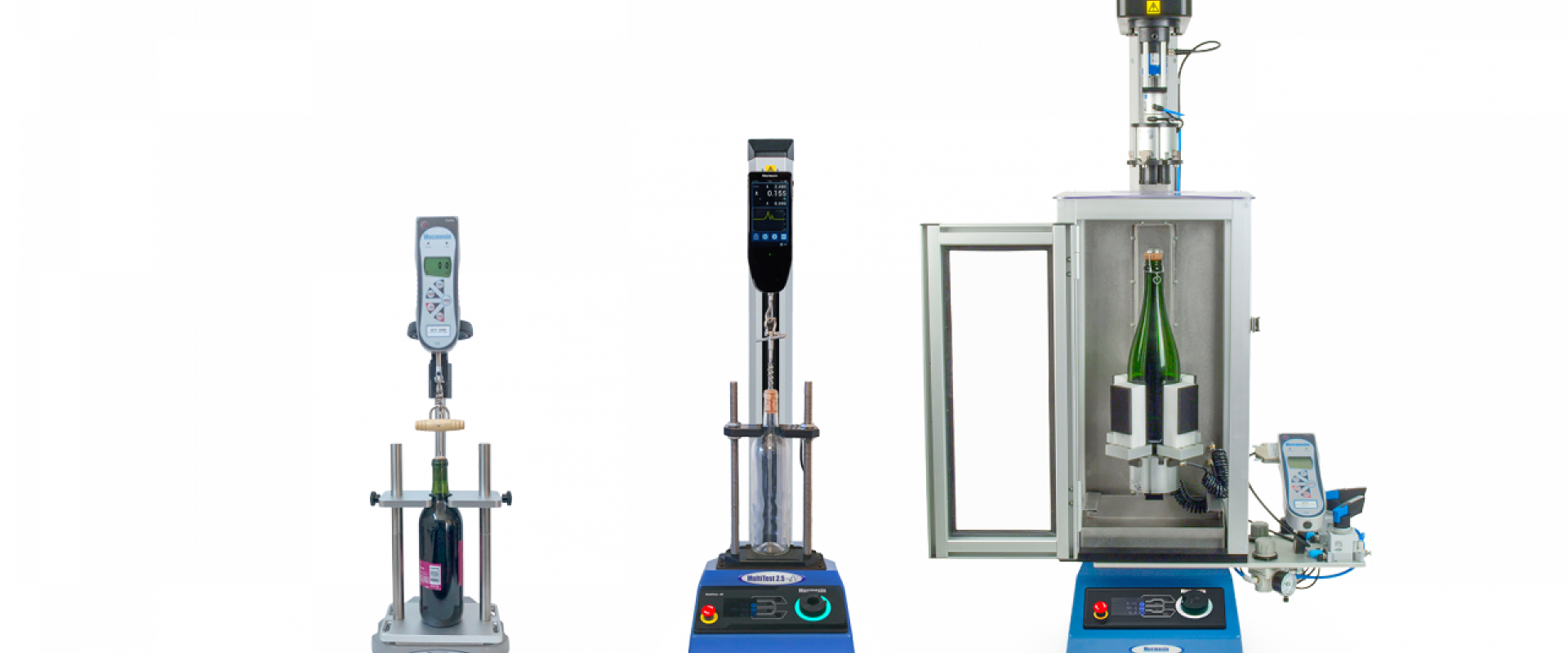

A basic manual cork extraction force tester.

An affordable and easy to operate motor-driven cork extraction force tester.

Explore our dedicated and semi-automated CombiCork system, for grading the un-corking torque of sparkling wines.

The benefits

Taking control of the testing of the mechanical performance of corks in-house enables your business to confidently select your ideal category stopper, safe in the knowledge that your product will reach your customer in perfect condition, and they will have easy and safe access to it when they are ready to enjoy it.

Automated cork testing solutions

Mecmesin have extensive experience in providing automated solutions for batch testing, including cork compression and recovery testing.

Get in touch with one of our friendly technical sales engineers to discuss your requirements.